Old Champlain Bridge Deconstruction, Montréal, QC

LOCATION: Montreal, QC

CLIENT: Nouvel Horizon Saint-Laurent (NHSL) – Pomerleau/Delsan AIM Partnership

VALUE: $400M +/-

YEAR: 2020-2023

ROLE: Bridge Deconstruction Engineer

CATEGORY: Bridge

The Old Champlain Bridge, joining Brossard to Montréal, Quebec, was open to vehicular traffic from 1962 to 2019. The bridge contained six travel lanes and was the busiest vehicular bridge in Canada upon its closure in 2019, when it was replaced by a new cable stayed bridge. The bridge was replaced due to ongoing structural deterioration, that was deemed economically unmanageable to maintain.

The bridge consists of 50-54m long+/- concrete girder approach spans, 4-78m structural steel approach spans and a 450m+/- main steel span consisting of two anchor spans and a suspended span which carried traffic over the Saint Lawrence Seaway.

Harbourside was named the Deconstruction Engineers on the project, responsible for all sequencing/phasing, means and methods, and temporary works design for the project.

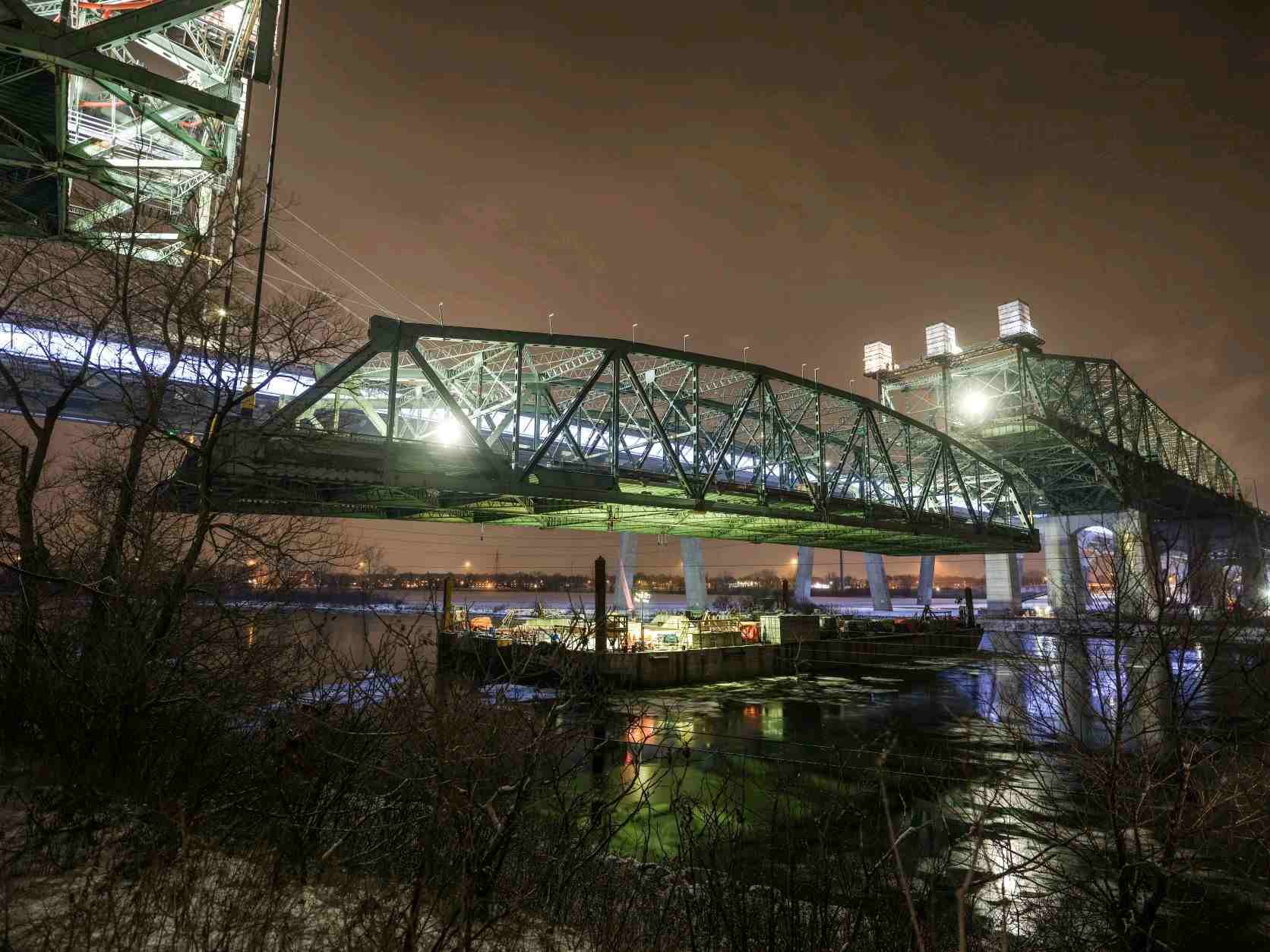

The main steel suspended span of the bridge, consisting of three variable depth steel trusses, spanned over the St. Lawrence Seaway Navigation Channel, making its removal particularly challenging. The suspended span was successfully lowered, in one piece, to a pair of interconnected barges, using six large strand jacks, in early January 2022 (Figure 1). The lowering was completed within a 48-hour operational weather window, in the cold temperatures of January to coincide with the winter closure of the Navigation Channel.

In addition to developing the sequence, cutting details, temporary member/wind restraints as well as designing the strand jack support frames and barge supports, Harbourside were also on-site during the lowering operation where Harbourside made vital/crucial decisions relating to unanticipated strand jack/truss load distribution and sensitive barge landing, on the fly in an efficient/effective manner, without delaying the time sensitive work operation while ensuring structural integrity of the bridge structure.The steel anchor/cantilever spans were deconstructed by installing and jacking load into two temporary towers (designed by Harbourside, Figure 2), disengaging the span near its centerline, and deconstructing the cantilevers in piece-by-piece methodology. The steel approach spans were dismantled by removing the orthotropic steel deck, and using two large crawler cranes to lift the steel trusses in pairs. The span was then safely disassembled using excavators with shears and other heavy equipment, except for re-use members which will be carefully removed in a piece-by-piece method.

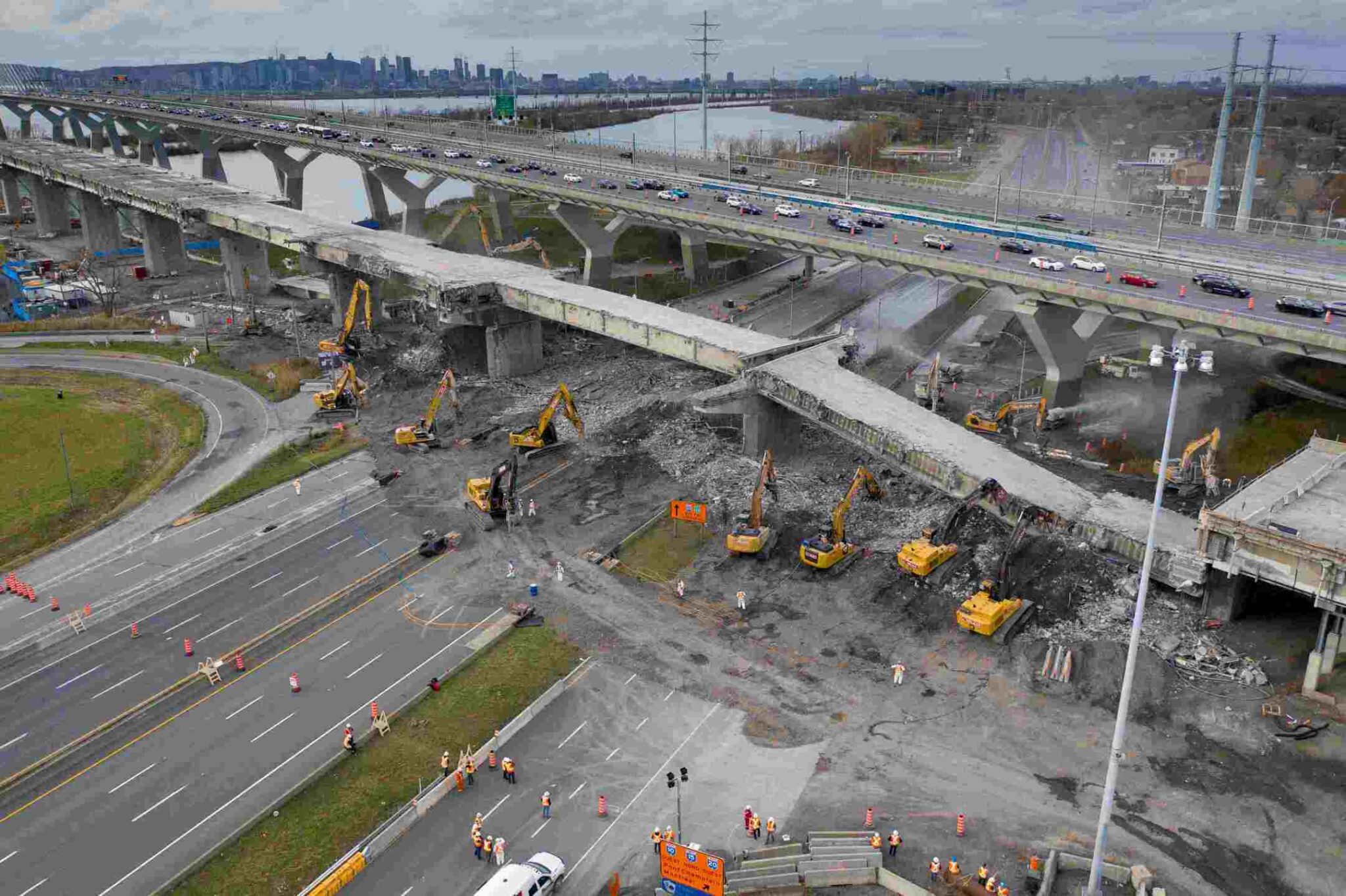

The concrete approach spans consisted of seven (7) pre-stressed concrete beams connected by transversely post-tensioned cast in place diaphragms and infill slabs. Following the removal of the reinforcing trusses (previously installed to support the deteriorated exterior girders) using cranes on the deck of the structure, deconstruction of the concrete approach spans followed one of two methods:

- Spans over land: Deconstruction in place, using temporary towers to support the partially demolished span.

- Spans over water: Lifting and removal of the span via a barge and then deconstruction of the span on the barge platform.

Method 1 consisted of sequentially demolishing the concrete girders in turn starting on one side of the structure and working towards the other side. Excavators with hammers and shears worked from the ground at the perimeter of the structure. For this deconstruction method two lines of temporary towers were required to support the girders during the deconstruction. Spans demolished using Method 1 were either over existing ground/highways or over a jetty built out into the St. Lawrence River.

In Method 2, a catamaran barge consisting of two 76.2m by 17.1m barges welded together, was outfitted with six 800 tonnes self-jacking towers and a platform superstructure. The superstructure (platform) for the temporary jacking system consisted of three longitudinal box beams spanning between jacking towers, two transverse built-up end beams and working surface (W-section stringers and steel plate).

To demolish a span, the barge was positioned under the span and the jacking towers raise the platform until in firm contact with the concrete span and then continue jacking until the span clears the existing bearings (maximum jacking height of 24.5m). The barge then translated the span clear of the concrete piers where the system was lowered to its lowest operating position. The barge list, trim, draft and deformation were continuously controlled by adjusting the position and volume of water in the barge’s ballast tanks. A winch barge and tugs were used to move the barge system. Once in the lowered position, two excavators used the platform on top of the jacking towers to demolish the concrete spans. The deconstruction proceeded sequentially starting with the girder on one side of the structure across to the other side. The excavators used shears and/or hammers to crush the concrete girders/deck. The debris fell on the platform and was removed at intervals by unloading onto separate transport barges. After all debris was removed, the barge was repositioned under the next span to repeat the operation.

Photo credit: JCCBI & Nouvel Horizon Saint-Laurent S.E.N.C.